Thank you for visiting our website. Your personal privacy is absolutely respected and protected by the website. To help you understand how the website collects, uses and protects your personal information, be sure to read the websitePrivacy Policy. Thank you!

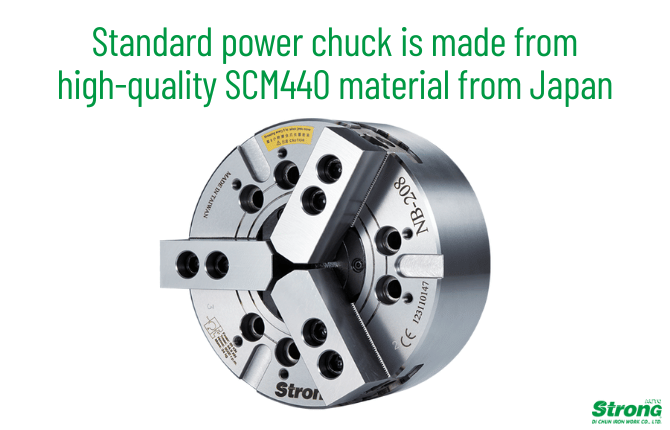

High-Quality SCM440 Power Chucks: Why Material Defines Accuracy, Durability, and Cost Efficiency

This article explains why SCM440 matters, how AUTO STRONG achieves Japanese-level quality at a more competitive cost, and how a high-quality chuck reduces the “hidden losses” of machining operations.

Learn more >>

Collet Chuck Installation & Maintenance Tips

This article will take you through the essential installation steps and key maintenance recommendations for collet chucks to help you optimize the performance of your CNC lathe automation.

Learn more >>

How to Choose the Right Collet Type: A Practical Guide for CNC Machining

At Auto-Strong (Di Chun Iron Work), with over 40 years of expertise in high-performance workholding, we design our CR and CRA series to be more than just components—they are efficiency boosters for your CNC lathe.

Learn more >>

Collet vs. Collet Chuck: What’s the Difference and Why It Matters in CNC Machining?

In CNC turning and precision metalworking, choosing the right workholding solution directly influences machining accuracy, productivity, and equipment utilization. Two of the most essential components in bar-stock machining are the collet and the collet chuck — yet many still confuse the two terms or treat them as the same hardware.

Learn more >>

What Is a Rotary Hydraulic Cylinder? Meet Our Award-Winning MB2091

In 2025, Di Chun Iron Works proudly introduced the newly developed MB2091 Thin-Type Hollow Rotary Hydraulic Cylinder, which was honored with the 33rd Taiwan Excellence Award. This recognition affirms its innovative design and outstanding performance.

Learn more >>

Recommended High-Precision Power Chuck Brands

In modern precision machining, selecting a reliable and high-performance power chuck brand is essential for ensuring machining accuracy, process stability, and productivity. Especially in industries such as automotive parts, aerospace, medical equipment, mold making, and aluminum wheel manufacturing, the rigidity, clamping force, and repeatability of the chuck directly influence production outcomes.

Learn more >>