Thank you for visiting our website. Your personal privacy is absolutely respected and protected by the website. To help you understand how the website collects, uses and protects your personal information, be sure to read the websitePrivacy Policy. Thank you!

THE GLOBAL MARKET

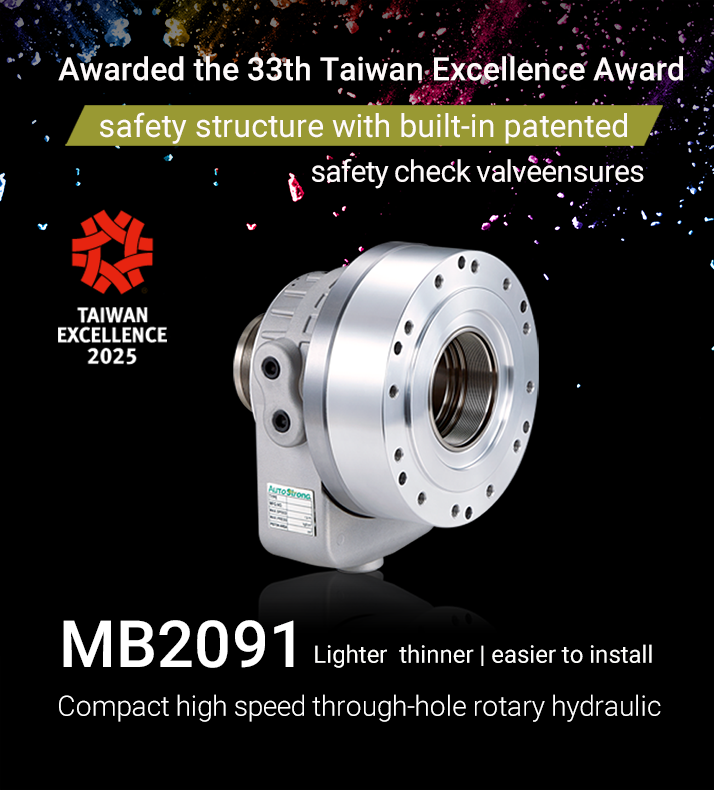

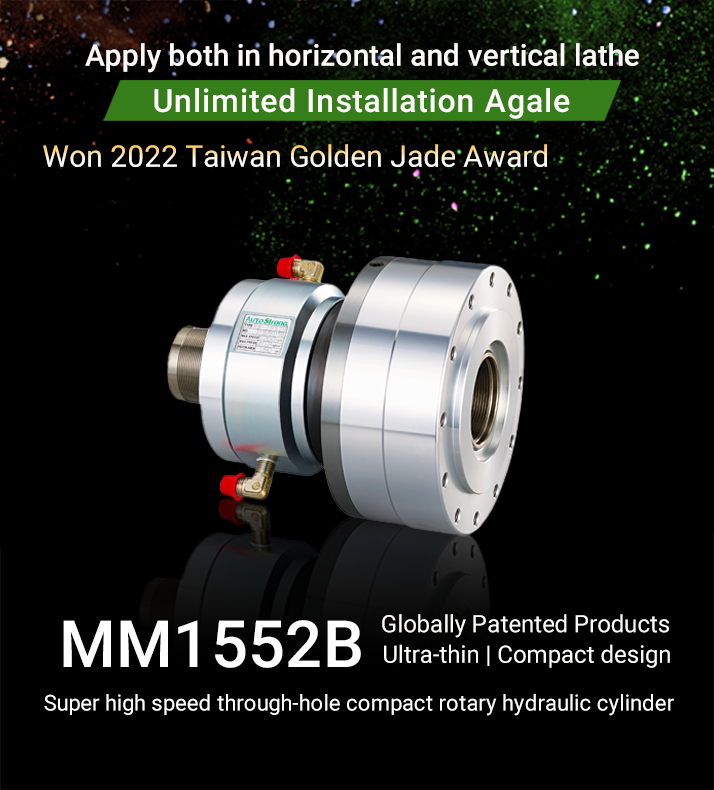

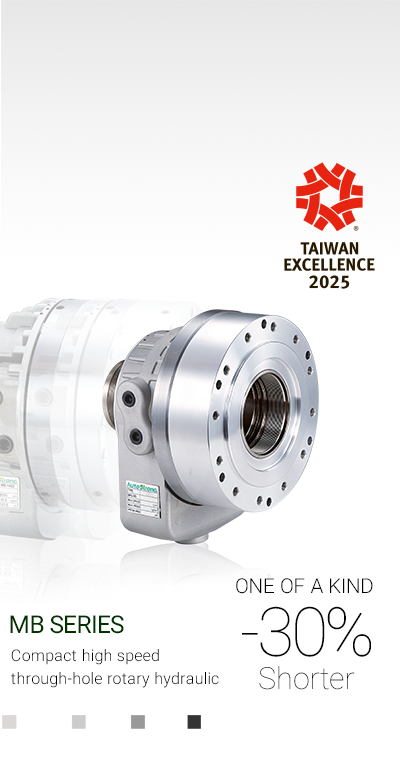

Under the brand “AutoStrong” Di Chun Iron Works has specialized in the manufacturing of power chucks, hydraulic cylinders, and collet chucks since 1974. earning the trust of wide range of customers and suppliers.

RESOUNDING INTERNATIONAL

Large wedge type non through-hole power chuck

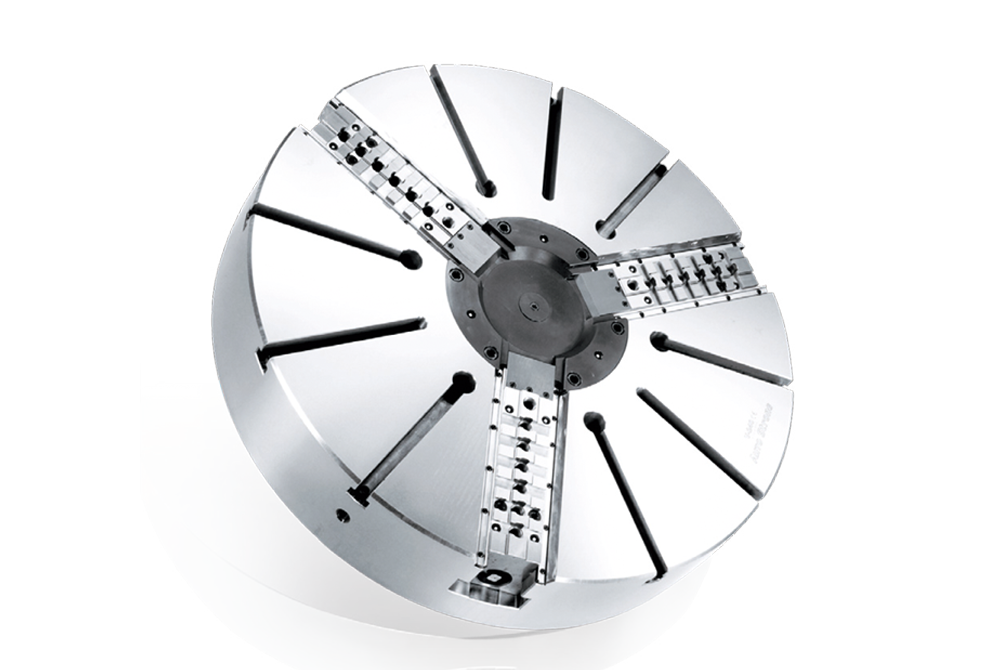

3-jaw extra large through-hole power chuck